rockwell hardness test mark|how to calculate rockwell hardness : dealers Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your . Results for : loira rabuda novinha. FREE - 12,272 GOLD - 12,272. . Loira rabuda cavalgando - espalhou.com. 9.6k 80% 2min - 360p. Rabuda 29 Aninhos , delicia de mais. 202k 98% 7min - 360p. Myke Brazil. Myke Brazil. 277.6k 100% 13min - 1080p. Loirafeet. Novinha ficou com a sua pequena buceta arregaçada com um pau enorme.

{plog:ftitle_list}

web28 de mar. de 2023 · You can use the ascend button to start over and receive a permanent buff on your next game if you feel like a fresh start. Get New Outfits. Capybaras are a spectacle without being dressed up, but .

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . American Standard Test Method (ASTM E 18) – Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials; The Rockwell hardness scale ensures that all .Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. The smaller the indentation value, .

ASTM E18 is the industry standard for Rockwell hardness testing of metallic materials. This specification includes both theory and standard practice statements. For those companies Nadcap accredited in heat treat where the .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

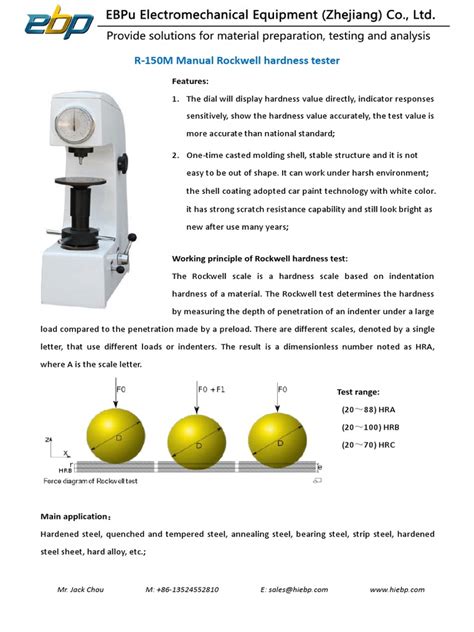

What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared . The concept of the Rockwell Hardness test is essentially similar to its counterparts. A sample material is fed on to either a digital or manual Rockwell hardness tester which would then drop a set load ending with an .The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine . Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. Rockwell invented the Rockwell hardness test. As a metallurgist for a large ball bearing company, he wanted a fast, nondestructive .

The Rockwell hardness test is used for macro hardness tests, which are generally defined as tests that use indentation loads below or equal to 1 kgf. Therefore, a ground surface is usually sufficient, and sometimes no preparation is required. Loads. Indentation time: 2-6 seconds;The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions. Rockwell hardness testing is popular due to its ease of operation including the absence of optical measuring equipment, a range of alloys may be measured, and readings can be obtained in a matter of seconds with both manual and more modern automated machines. ASTM E18 is the industry standard for Rockwell hardness testing of metallic materials.Rockwell hardness test is one of the most common indentation hardness tests developed for hardness testing. In contrast to the Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). . Eberhart, Mark (2003). Why Things Break .

These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table

rockwell hardness testing chart

rockwell hardness tester diagram

One of the most common indentation hardness tests used today is the Rockwell hardness test, and although less widespread, the Brinell and Vickers hardness tests are also utilized. . This method has resulted in efficient, fast and accurate portable hardness testing results. However, when a mark or indentation on the workpiece must be avoided .Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). The load is applied for a .

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality .

Rockwell Test Mark Left in the Die See Planchet Errors HERE . Definition: A common device used to measure the hardness of metals in the U.S. Mint is the Rockwell hardness tester. It measures the depth of penetration of a steel or diamond-tipped pin relative to the applied force. A Rockwell test mark will appear on a die face as a small pit. The rating of softer steel range between 45-54 HRC, while harder steel ranges above 55 HRC. Rockwell hardness is important in the quality control of steel and the selection of steel to be used in different kinds of . Rockwell hardness testing is a common analytical technique for evaluating the hardness of metallics and synthetic materials. Rockwell Hardness Test. While hardness testing does not provide a direct assessment of product or raw material performance qualities, hardness correlates directly to qualities like strength and wear resistance. .

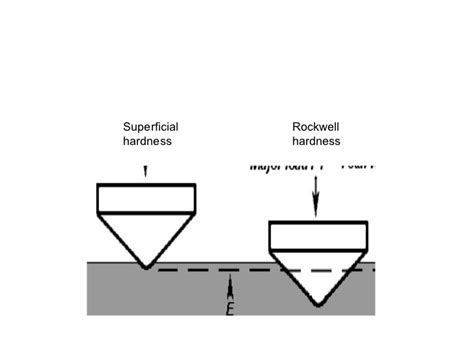

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C-scale (HRC 20-70). Soft materials are tested using a 1/16" carbide ball indenter in the B-scale (HRB 25-100). Very hard materials are tested using a 120 diamond indenter in

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine. The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels. .ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two force levels using the specific conditions defined in Clause 7. The specified preliminary force is applied5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

Rockwell hardness testing is a fast and inexpensive test. The simplicity in the operation of a Rockwell hardness testing machine provides the added advantage that Rockwell hardness testing does not generally require a highly skilled operator to perform. . The thickness of the specimen should be such that a mark or bulge is not produced on the .

The Rockwell hardness test is a very useful and reproducible one provided that a number of simple precautions are observed. Most of the points filled below apply equally well to the other hardness tests: . The thickness of the specimen should be such that a mark or bulge is not produced on the reverse side of the piece. It is recommended that .

rockwell hardness test theory

research on negative impact of timed tests in elementary

WEB🏆 Gerador de tabela de campeonato. Gerador de tabela da liga para o seu torneio de futebol, fácil de usar com CAMPIONI.BIZ , Gerencie seu torneio de futebol a partir do registro de times de futebol e todas as partidas registrando vitórias e derrotas, pontos e um ranking que é criado automaticamente.

rockwell hardness test mark|how to calculate rockwell hardness